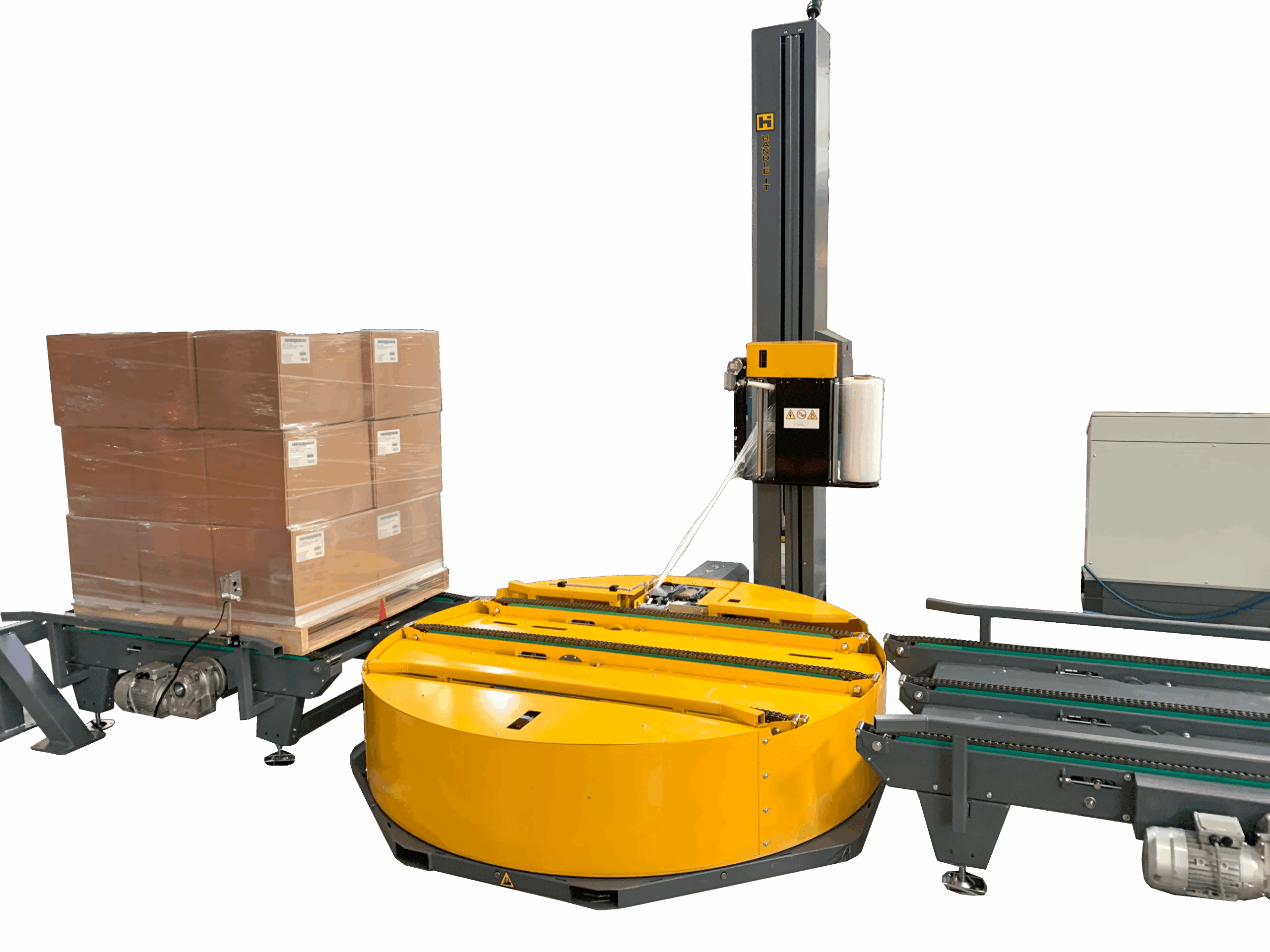

Pallet wrapping machine repair for steady load securing in routine use

Just How to Make best use of Efficiency With a Pallet wrapping Machine: Common Repair Tips

Making best use of effectiveness with a pallet wrapping machine requires a tactical method to repair and maintenance. Routine checks are necessary to ensure all elements function smoothly. Common problems such as inconsistent film tension and jamming can disrupt procedures. Addressing these problems without delay can improve efficiency. Understanding the subtleties of changing stress and preserving tidiness is similarly important. What certain steps can be required to guarantee peak efficiency?

Routine Maintenance Checks

Normal upkeep checks are necessary for guaranteeing the ideal efficiency of a pallet wrapping machine. These checks not just boost the long life of the equipment but likewise boost functional performance. Regular evaluations ought to include taking a look at the equipment's electric parts, ensuring that all links are totally free and secure from deterioration. The film dispensing system should be looked for proper placement and tension to prevent functional disturbances. In addition, oiling relocating components minimizes friction and wear, preserving smooth functionality. Operators should also examine the control panel for any abnormalities in analyses or performance. Regular maintenance cultivates a proactive technique to devices care, inevitably bring about lowered downtime and raised performance in the wrapping procedure. Sticking to a set up maintenance strategy is crucial for ideal efficiency.

Fixing Common Problems

Changing Damaged Components

Changing worn-out parts is important for preserving the optimal efficiency of a pallet wrapping maker. Normal inspections assist identify parts that reveal indications of wear, such as the film carriage, rollers, or drive belts. These components can break down over time, resulting in ineffectiveness in wrapping procedures. When substitute is essential, it is essential to pick premium components that match the device's requirements to assure compatibility and top efficiency. Professionals should adhere to the maker's standards during the substitute process, as incorrect installment can cause further issues. Furthermore, maintaining a supply of typically needed parts can reduce downtime, permitting quicker repair services and keeping performance degrees. Proactive maintenance and prompt replacements are essential to prolonging the maker's life-span.

Changing Tension and film Settings

Preserving excellent efficiency of a pallet wrapping maker extends beyond changing damaged components; it likewise involves fine-tuning the tension and film settings. pallet wrapping machine repair. Appropriate stress is vital for accomplishing optimal load security during transportation. If the tension is as well tight, it may harm the load, while inadequate tension can lead to loosened wrapping and potential moving. Operators should frequently inspect and adjust the stress setups according to the particular demands of the load being wrapped

In addition, choosing the right film type and density is essential for ensuring reliable wrapping. Thicker movies provide enhanced strength yet might call for greater tension setups. On the other hand, thinner films might be a lot more affordable yet can endanger load safety otherwise appropriately tensioned. Normal adjustments will certainly make best use of efficiency and lessen material waste.

Keeping the Machine Tidy and Moisturized

Usually forgotten, keeping the pallet wrapping maker tidy and lubed is crucial for guaranteeing peak performance and longevity. Normal cleansing helps stop the buildup of dust, particles, and residue that can impede mechanical features. It is recommended to wipe down surface areas and get rid of any type of collected products after each usage. In addition, proper lubrication of moving components reduces rubbing, lessens wear, and prolongs the life expectancy of the device. Operators must seek advice from the supplier's standards for suggested lubes and upkeep timetables. Performing routine assessments to identify any type of indications of rust or rust can likewise stop even more substantial concerns down the line. Adhering to these practices will not only enhance efficiency but likewise advertise risk-free procedure of the pallet wrapping machine.

Frequently Asked Inquiries

How Commonly Should I Change the Pallet wrapping film?

The regularity of replacing pallet wrapping film depends upon usage and wear. pallet wrapping machine repair. Commonly, it should be replaced when signs of damage, tears, or excessive extending take place, ensuring suitable efficiency and security of the covered items

Can I Make Use Of Different Kinds of Movies With My Machine?

Various sorts of films can generally be used with pallet wrapping equipments, yet compatibility depends upon the device's specifications. Users need to speak with the supplier's guidelines to guarantee peak efficiency and prevent potential damages to the devices.

What Safety Precautions Should I Take While Running the Maker?

When running a pallet wrapping maker, one ought to wear ideal individual protective equipment, guarantee correct training, preserve a clear office, and frequently evaluate the machine for any kind of possible threats to guarantee secure procedure.

How Do I Train New Worker to Utilize the Pallet wrapping Device?

To train brand-new staff members on the pallet wrapping equipment, one should give thorough demos, thorough guidebooks, and hands-on practice. Routine analyses and responses will certainly enhance their skills and assure risk-free, reliable operation.

What Are the Indications That My Equipment Needs Expert Maintenance?

Indicators indicating a requirement for specialist servicing include uncommon noises, irregular wrapping, regular error messages, and visible endure parts. Timely interest to these problems can prevent more damage and assurance optimal machine performance.

Regular maintenance checks are vital for making certain the optimal performance of a pallet wrapping device. Replacing damaged components website is crucial for keeping the optimal efficiency of a pallet wrapping equipment. Keeping ideal performance of a pallet wrapping machine prolongs past replacing worn-out parts; it likewise includes make improvements the tension and film settings. Typically neglected, keeping the pallet wrapping device clean and lubricated is vital for ensuring peak performance and durability. Various kinds of films can usually be used with pallet wrapping devices, but compatibility depends on the maker's requirements.